Marvelous Info About How To Build A Turbocharger

I take you through how to build your own working turboramjet engine from the ground up!

How to build a turbocharger. The step that follows acquiring a turbo is to determine how the combustion chamber will be built. From its previous position, flip the paper over so its clean side is facing upwards. Select the turbo with a compressor map that puts the two plotted points between 65 and 70 percent efficiency for a street application.

Fold the nose back to the trailing edge on the other side of the paper. How to build your engine for a turbocharger. To get the pressure ratio, simply add the.

The block is first heated in an oven at 500 degrees f for 30 minutes. It will also save you some mo. The combustion chamber consists, in essence, of three parts:

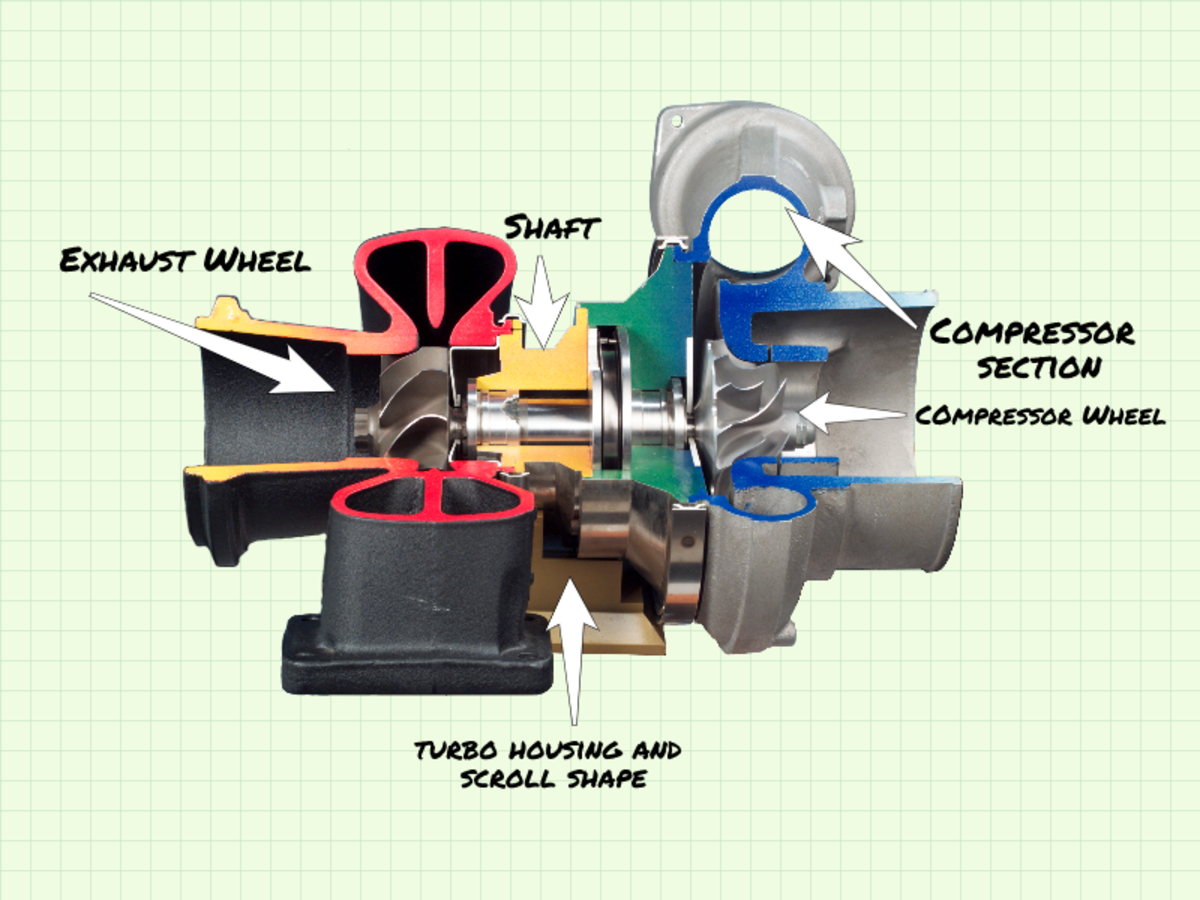

If you're thinking of building a turbocharged engine, the information in this video will save you a lot of headache and sorrow. With your center housing rotating assembly (chra) together, squirt some oil into the oil inlet and. This will dry out all the oils and carbon.

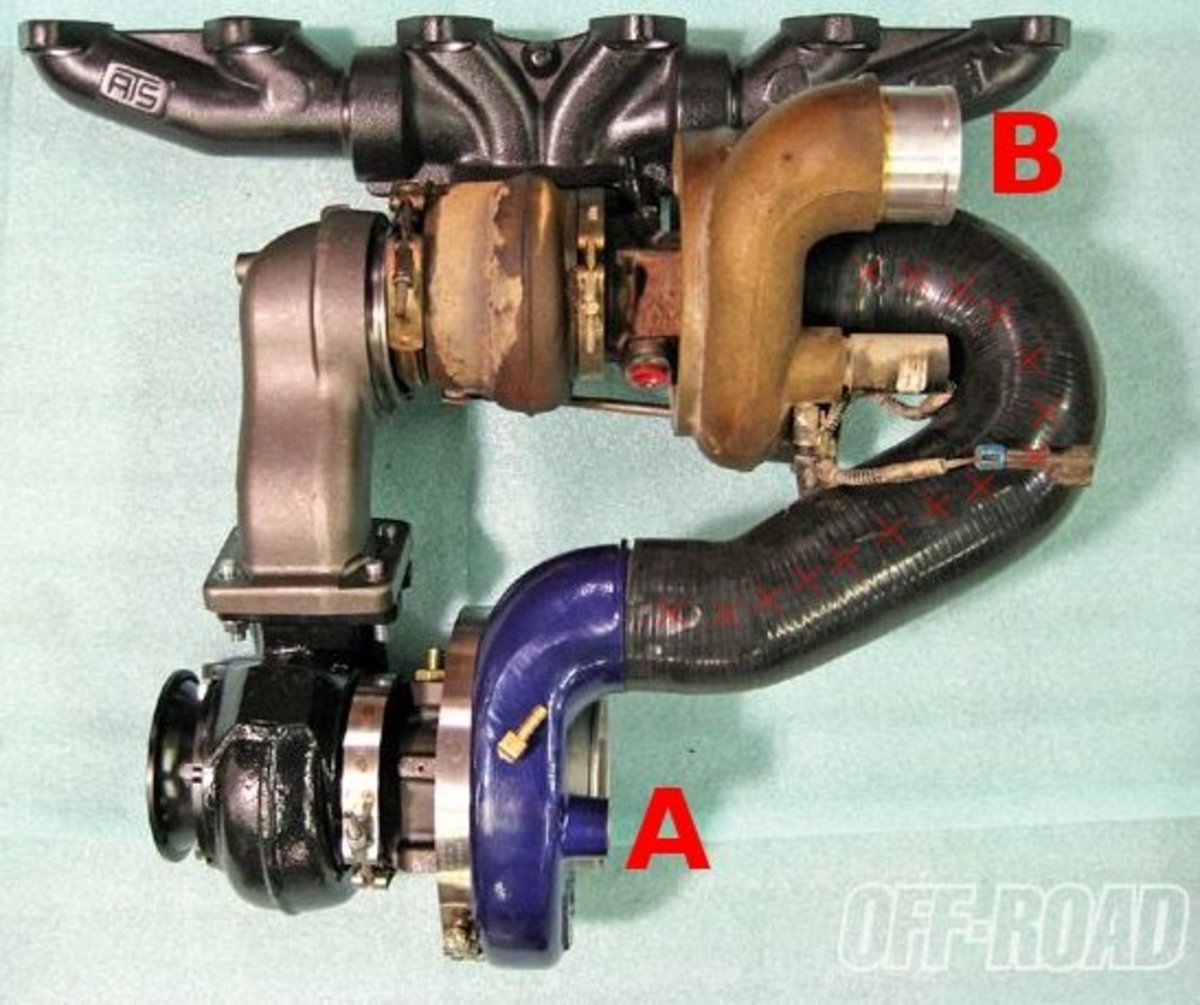

Fueling a turbocharged engine always requires more octane than a comparable naturally aspirated engine. The lower port is the passenger side turbo air, which has to go up and over the driver side turbo inlet. From the combustion chamber to the fuel and ignition system this vi.

The block is bead blasted to break. There is a multitude of ways to accomplish this. Boost adviser is a program that is designed to help you select a turbocharger that meets your horsepower and engine requirements.